- Analytical methods

-

PLA 3.0

- About PLA 3.0

-

Analyze your data

- Analyze Biological Potency Assays

- Analyze quantal response assays

- Analyze the dose-response relationship

- Analyze the endotoxin concentration in a substance

- Develop Equivalence margins

- Determine the potency of antibiotics

- Perform a curve comparisons

- Perform a Linearity-of-dilution assessment

- Perform a sophisticated statistical process control

- Perform combination calculations

- Import your data

- Supporting add-ons

- Compliance features

- Deployment

- Try & Buy

- PLA 3.0 Academy

- Support

- Company

Newsletter - 30.08.2021

Statistical process control for Bioassays with PLA 3.0

Dear Sir or Madam,

Statistical process control is much discussed in the last weeks and one of the hot topics at the next BEBPA - EUR Bioassay Conference.

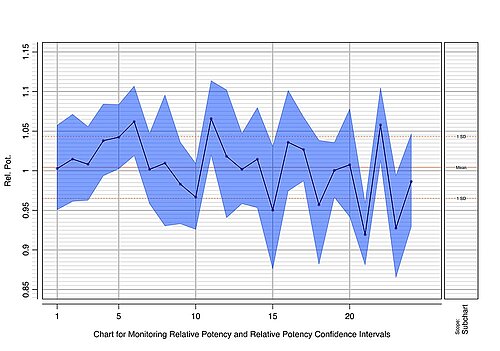

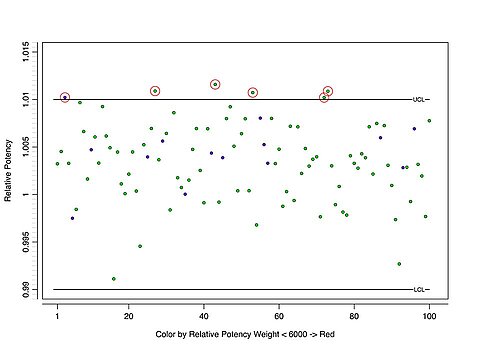

Did you know that our Control Chart Package* allows sophisticated statistical process control by plotting Shewhart I-Charts as recommended in the USP <1010>? It provides visualization options for intervals, subcharts and sidecharts, and allows you to define colors by a secondary characteristic. You can also define rules based on events and time frames.

*Please note: The current version of the package is a technology preview. It has not been released yet and has not been finally qualified for use. How to activate the technology preview?

The following list highlights the USP <1010> methods supported by the Control Chart Package:

Extensive and independent configuration options on I-charts

Individual chart (I-Chart). I-Charts monitor data such as measurements and regression parameters at regular intervals, with each data point within the chart representing a sample or an observation respectively.

All charts generated by the Control Chart package are I-Charts. You can manually add the chart data, or aggregate it from other PLA 3.0 documents such as Quantitative response assays or Dose-response assays.

Parameter statistics to view descriptive details for every chart

The Control Chart package automatically calculates the following parameter statistics for each data series: mean and median, standard deviation (SD), coefficient of variation (CV), 1st and 3rd quartile, min. and max. values, number of values, and missing values. The statistics are displayed on the Dashboard and in the reports.

In addition, you can configure confidence intervals and sidecharts to deeply analyze your data.

Statistical process control by defining control rules and control limits

Control limits define a range of acceptable values, determined by an upper and a lower limit. Any value outside of this range is considered to be a rule violation and needs to be marked as such.

Use the Control Chart Package to set up rule sets with independently defined upper and lower control limits. These rules will be drawn as horizontal lines on your control chart.

Nelson & Western Electric Company (WECO) rules

These decision rules allow detecting out-of-control or non-random conditions on control charts, based on deviations from the mean. They are also capable of detecting patterns or trends. For example, you can apply Nelson rule 3 to detect when six (or more) points in a row are continually increasing (or decreasing).

The Control Chart Package provides a set of predefined control rules (Nelson rules 1 to 8 and WECO rules 1 to 4) and also allows you to set up user-defined rules. You can also base control rules on parameter statistics of historical data. In contrast to control limits, where the limits can be defined independently, a control rule automatically applies to both the upper and the lower limits.

Calculation of the standard deviation

USP <1010> recommends calculating the standard deviation using differences between consecutive data points instead of comparison to the overall mean.

The Control Chart Package supports both methods for estimating the standard deviation.

Please click to read more about the Control Chart Package

Best regards

Mathias von Gellhorn

Marketing Manager

Stegmann Systems GmbH, Raiffeisenstr. 2, 63110 Rodgau, Germany

Phone: +49 (6106) 77010-0, Fax: +49 (6106) 77010-190

www.stegmannsystems.com